|

|

|

#11 |

|

Guest

Posts: n/a

Casino cash: $ |

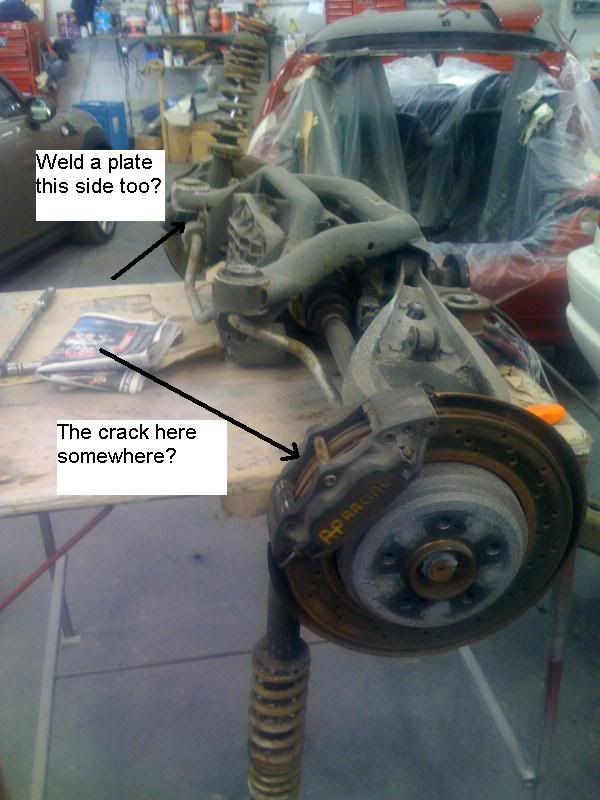

An update, with pictures

1. image one shows the crack and the weak spot weld welded up.  2. shows the reinforceing plate in position ready to weld.  3. shows the plate seam and plug welded into position.  4. shows the welds ground down ready for etching primer.  5. o/s rear mount.  6. n/s rear mount.  7. a coat of underbody colour on top of etch primer.  8. o/s rear all painted up.

|

|

|

|

#12 |

|

S6, Sport On, Traction Off

|

Looks a good fix steve!

|

|

|

|

|

|

#13 |

|

CSL Register Uber-poster!

|

Good job Steve that should sort it

Ready for the Csl ring LOL |

|

|

|

|

|

#14 |

|

S5, Sport On, DSC M-track

|

Thanks for that Richie

Looks a similar fix to what many of the american lads are doing. I remember one not so long ago getting fixed - the lads there made it look oem. Reason for his cracking though cos he had around 650 whp

|

|

|

|

|

|

#15 |

|

S5, Sport Off, DSC M-track

Join Date: Jan 2009

Posts: 527

Casino cash: $1272  |

Did 'you' just weld up the one side, or do both as the same time?

|

|

|

|

|

|

#16 |

|

Guest

Posts: n/a

Casino cash: $ |

|

|

|

|

#17 |

|

S5, Sport Off, DSC M-track

Join Date: Jan 2009

Posts: 527

Casino cash: $1272  |

I know the crack was only on one side, but by strengthening one side only, would it put more pressure on the 'same spot' on the other side? I wondered if not put a strengthening plate on both sides of the car (not one 'below' and one 'above'). Does that make sense?

Edited to say: Like this?

Last edited by Nords; 21-03-2009 at 07:30 PM. |

|

|

|

|

|

#18 |

|

Driving it like I nicked it

Join Date: Sep 2008

Posts: 2,099

Casino cash: $13060  |

I think the crack is on the car, not the subframe and the photos are captioned as N/S and O/S so I assume both sides have been addressed

|

|

|

|

|

|

#19 |

|

S5, Sport On, DSC M-track

Join Date: Jun 2008

Location: Auckland, New Zealand

Posts: 1,434

Casino cash: $13579  |

Some of the guys in the US cut open the boot floor (as recommended by Turners repair instruction) - which then allows you access to the "otherside" of the subframe floor mount plate and weld up the other side and do further rust proofing. They only do this to the most extreme cases of subframe floor mount tear though. For those interested in the structural foam method the defect number on the TIS is 41 11 91 01 00 TIS 41 03 03 (025) |

|

|

|

|

|

#20 |

|

S5, Sport Off, DSC M-track

Join Date: Jan 2009

Posts: 527

Casino cash: $1272  |

|

|

|

|

|

|

|